In terms of maintenance, there are two main things to focus on with regard to the COMMANDassurance ProbeA probe device mounted in the side of a bin to measure the moisture content of aggregate materials such as sand.:

- Keeping the battery charged

- Keeping the probe clean

The probe’s batteries are charged by a solar panel. For this to work efficiently, the solar panel has to be placed at the top of the drum (under direct sunlight) when the truckAll machines used as a means of production on a construction site or at a batch plant. is parked and the solar panel must be kept clean. It is possible to use a cable to recharge the probe when required, should the solar panel not charge enough for a period of time due to meteorological conditions or damage.

When the probe is positioned properly in the drum and the washing procedure is performed correctly, there is little maintenance to keep the probe clean and free of hardened concrete. Due to the stickiness of concrete, there is always the possibility that the probe may get covered by concrete, which can build up over time.

Simple tools, alarms, and procedures are used to help keep the probe in good working condition.

Keeping the battery charged

Connect the charger from the truck battery or wall charger to the probe SAE connector when the battery is running low.

A 12-hour charging cycle is recommended.

Keeping the probe clean

Concrete tends to stick to metal and requires proper cleaning while in a fresh state to avoid buildup. Since the probe is made of stainless steel, it tends to remain clean. The probe’s position, the cleaning process and some other parameters related to delivery may cause progressive concrete buildup on probes. As shown in the pictures below, Truck 249 shows some buildup. In rare cases, the base of the probe is completely stuck in concrete, making the probe difficult to remove.

|

|

|

|

|

Two probes after six months in a ready-mix truck |

|

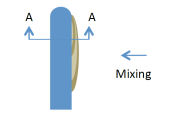

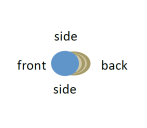

The side of the probe that goes first in the concrete when mixing is referred to as the front and is almost always clean. The progressive buildup illustrated in the images below is always on the back side of the probe. When concrete builds up, it is usually weak and the abrasive action of the concrete quickly cleans the concrete on the front and on both sides of the probe. This allows the probe to maintain its surface area in the mixing direction and therefore the buildup on the back of the Probe does not affect the pressure measured by the probe while moving through fresh concrete.

|

|

If a probe is completely stuck in concrete, the only solution is to use a hand-held jack hammer. When the jack hammer is used with caution, it is usually possible to clean and remove the probe without causing any damage.

Visual inspection

We recommend that the driver visually inspect the probe at least once per week.

It is recommended to perform the visual inspection with a powerful concentrated LED hand-held flash light or another appropriate light source. Based on the previous images, one can see some buildup at the back of the probe. This amount of buildup is acceptable and does not affect the probe’s performance if it is only on the external tube. As long as the sides and the joint between the base and the external tube are clean, the measurements taken by the probe are not affected.

It usually is not possible to check if the probe’s base is free from concrete with a visual inspection. If pressure is measured when there is concrete in the drum and it shows no pressure when it is empty, the base is likely free of hardened concrete.

Removing the probe

Removing the probe is a recommended method for inspection to assess whether it is free of any concrete buildup. Simply dismount the solar panel to gain access to the probe. Unscrew the probe.

Cleaning the probe (removed)

Do not fix the probe in a grip to perform this step, but rather place the probe’s external tube directly on a hard surface as shown below. Gently hit the concrete with a hammer from the side and then it should separate easily.

Cleaning the probe (still fixed)

If it is not possible to remove the probe from the drum or trap door, then remove hardened concrete with a small hammer. Brace the probe against a heavy hammer as an anvil. The large hammer used as an anvil pushes against the probe and reduces the stress in the loadThe total amount of concrete or asphalt that is being or has been batched for delivery. cell by absorbing the shock inertia. The pictures below show the recommended procedure to remove hardened concrete from a free standing external tube.

|

|

Additional resources